Wow, I see my last post was in September! You would think I've been a busy girl. Yes and No. September was around the time I had cataract surgery on my right eye. After a few weeks, I had the other eye done. Then I had to wait for new glasses. Before I got the new glasses, I participated in two craft shows. Writing those tiny labels was the hardest thing. But all is well again .... my vision has really improved.

My friend Drewcilla is an exceptional glass artist. She has been making custom night lights for years, selling them in her Etsy shop. Recently she started using fusible decal paper by Bullseye. She used a black and white printer to transfer the images to the decal paper. The images were then fired on glass, and they fired to a lovely sepia tone. How simple could that be, I thought. I have a black and white printer that I've used many times for etching images on metal, so I was pretty confident it would work. You can imagine my disappointment when I opened the kiln door and saw pieces of glass with NO IMAGES on them! I tried it a second time with the same result. So it was time to buy a new printer!

After wasting many sheets of the decal paper and getting some technical assistance from Canon, I finally managed to get three successful pieces printed and fired.

These are my dogs Sarah and Sammy. Sarah, on the left, is a poodle mix and is 14 years old. Sammy is a rescue dog I've had for a few months. He's two years old, is wild and crazy, and has brought so much fun and joy to his new home. He and Sarah play constantly.

This is Sarah again. She is beautiful.

This is Charlie, who we lost earlier this year. Such a sweetheart.

This was a great project! If you are interested in making night lights, I'd be happy to share my information with you.

Showing posts with label fused glass. Show all posts

Showing posts with label fused glass. Show all posts

Saturday, December 22, 2018

Sunday, November 8, 2015

PROM PLUS HOLIDAY BOUTIQUE!

I've been busy getting pieces ready for Saturday's Holiday Boutique. It should be fun. If you live near La Crescenta, CA, please come visit the show. It benefits Crescenta Valley High School's Prom Plus, providing safe venues to have fun after the prom. I will have a sampling of fused and stained glass, ceramics, gourds and some metal pieces .. everything except for jewelry. Apparently that category was already filled by the time I entered the show.

The last couple days I've been making Christmas ornaments. Here are a few.

HOPE TO SEE YOU ON SATURDAY!!

The last couple days I've been making Christmas ornaments. Here are a few.

HOPE TO SEE YOU ON SATURDAY!!

Tuesday, September 15, 2015

CREATING A STENCIL WITH THE CAMEO SILHOUETTE

The Cameo Silhouette is an electronic cutting machine. I first became interested in buying one when I worked with metal clay. You can put a sheet of rolled out metal clay on the cutting mat and cut the design you have created! Amazing! Of course, if it cuts clay, it can also cut paper, card stock, stencil material, vinyl ... You can create your own stamps, engrave on metal, print stickers with your computer and cut them out with the Silhouette ...

A couple days ago I saw instructions for creating a stencil on one of the Facebook groups I belong to. The member was using the same kokopelli image I had purchased from the Silhouette store. It looked so simple I thought I could do it. I did not simply want to cut around the image. I wanted to create a stencil about 6" square with the figure in the center. Then I could use it to sift powder through the stencil image onto glass. The problem was that it had the "floating" designs in the body that were not attached to anything. The instructions showed how to create long skinny rectangles using the Silhouette software that attached the loose parts.

I spent the entire afternoon and next morning following her instructions ... and it was not working. I finally posted on Facebook explaining my problem and asking her to go through part of the instructions for me ... slowly. She was so nice and posted another addition to the instructions. Unfortunately, it still did not work.

I decided to send an email to her privately ... it was kind of embarrassing to be the only one who could not do this. After going back and forth a few times, with my sending photos of my computer screen showing steps that did not work, she asked me to send the image I had. She used my image with her instructions and, guess what ... it did not work for her! She kindly said "Now I understand ..." my image would work if I would first "Ungroup", then "Make compound path". Ha. I have lots to learn, but did those two steps, then followed the rest of her instructions, and the final image was the same as hers. I slept well that night.

The problem was still not solved, as I could not print out a TRUE stencil with the image in the center. So I created more skinny rectangles that would attach the image to the stencil itself. You can see all those extra lines.

The result was that I created a real stencil I can use!! Yippee!! The final version below is printed on nice stencil material and measures about 6" square. I can make handles using masking tape, set the stencil on the glass ... then sift powder and lift the stencil up and away with the handles. A little touchup will be needed to fill in some of the lines. This was a great learning experience. Frustrating ... yet very rewarding.

A couple days ago I saw instructions for creating a stencil on one of the Facebook groups I belong to. The member was using the same kokopelli image I had purchased from the Silhouette store. It looked so simple I thought I could do it. I did not simply want to cut around the image. I wanted to create a stencil about 6" square with the figure in the center. Then I could use it to sift powder through the stencil image onto glass. The problem was that it had the "floating" designs in the body that were not attached to anything. The instructions showed how to create long skinny rectangles using the Silhouette software that attached the loose parts.

I spent the entire afternoon and next morning following her instructions ... and it was not working. I finally posted on Facebook explaining my problem and asking her to go through part of the instructions for me ... slowly. She was so nice and posted another addition to the instructions. Unfortunately, it still did not work.

I decided to send an email to her privately ... it was kind of embarrassing to be the only one who could not do this. After going back and forth a few times, with my sending photos of my computer screen showing steps that did not work, she asked me to send the image I had. She used my image with her instructions and, guess what ... it did not work for her! She kindly said "Now I understand ..." my image would work if I would first "Ungroup", then "Make compound path". Ha. I have lots to learn, but did those two steps, then followed the rest of her instructions, and the final image was the same as hers. I slept well that night.

The problem was still not solved, as I could not print out a TRUE stencil with the image in the center. So I created more skinny rectangles that would attach the image to the stencil itself. You can see all those extra lines.

The result was that I created a real stencil I can use!! Yippee!! The final version below is printed on nice stencil material and measures about 6" square. I can make handles using masking tape, set the stencil on the glass ... then sift powder and lift the stencil up and away with the handles. A little touchup will be needed to fill in some of the lines. This was a great learning experience. Frustrating ... yet very rewarding.

Wednesday, September 2, 2015

MORE...SIFTING POWDER ON GLASS

My first experiments using clear powder on iridescent glass were so successful, I cut more glass to make three more pieces. The collection of dried leaves I have is so fragile, I decided to trace and cut a few using card stock. Why not, right?

I sifted on the powder and carefully removed the cutouts. The powder looks kind of thick in places, but since I managed to remove the cutouts without spilling, I decided this one was a keeper. It measures 4" x 13".

In one of the tutorials I have using powder, the person recommended using a WaxVac, a device you would buy for your ears. I found one at the local Walgreen's. I put it together with the two AA batteries it needed, and it worked great for vacuuming up excess powder around the edges or in wider spaces. A suggestion made in the tutorial was to insert a mini straw into the device for the small spaces. Unfortunately, I had finished the three pieces before I read this, so... next time.

I used a stencil I had cut with my Cameo Silhouette for one of the pieces. A floral design in a circle. This piece is a 6" square.

Then a stencil I had with trees. This is also 6" square.

Here are the three pieces in the kiln. Keeping my fingers crossed!

When you fire in the evening, the pieces are still around 150 degrees when you get up in the morning. So you wait and wait. And you always feel like that little child on Christmas morning! The piece with the floral design turned out great.

The piece with the trees is a little too dark, and it had "wrinkles" in the corners. It's still ok ... but it gets added to my collection.

I really liked the piece with the cut out leaves. They don't look as delicate as real leaves, but passable.

I sifted on the powder and carefully removed the cutouts. The powder looks kind of thick in places, but since I managed to remove the cutouts without spilling, I decided this one was a keeper. It measures 4" x 13".

In one of the tutorials I have using powder, the person recommended using a WaxVac, a device you would buy for your ears. I found one at the local Walgreen's. I put it together with the two AA batteries it needed, and it worked great for vacuuming up excess powder around the edges or in wider spaces. A suggestion made in the tutorial was to insert a mini straw into the device for the small spaces. Unfortunately, I had finished the three pieces before I read this, so... next time.

I used a stencil I had cut with my Cameo Silhouette for one of the pieces. A floral design in a circle. This piece is a 6" square.

Then a stencil I had with trees. This is also 6" square.

Here are the three pieces in the kiln. Keeping my fingers crossed!

When you fire in the evening, the pieces are still around 150 degrees when you get up in the morning. So you wait and wait. And you always feel like that little child on Christmas morning! The piece with the floral design turned out great.

The piece with the trees is a little too dark, and it had "wrinkles" in the corners. It's still ok ... but it gets added to my collection.

I really liked the piece with the cut out leaves. They don't look as delicate as real leaves, but passable.

Sunday, August 23, 2015

SIFTING POWDER ON GLASS PLATES

It's been cool enough the last few days that my energy level has gone up! And cool enough to work in the garage and be creative. I've been wanting to try two techniques where you sift powder directly onto glass using a stencil or dry leaves. Bullseye has videos of these processes that are very helpful.

My first projects were done with a wonderful bamboo stencil. I made two similar plates, so I'll only show you one. I first made masking tape handles for the stencil so it could be easily removed from the glass. I used French vanilla glass and dense white powder for these pieces. In this photo, the stencil sits on the glass piece, ready to receive powder.

I've sifted the powder onto the stencil.

Well, the stencil wasn't that easy to remove, as the powder weighed the stencil down so lots of it fell off and the powder image was not crisp. I dumped several stencils of powder and finally got a fairly good image. Next time I'll try adding BBQ skewers or a cardboard frame around the stencil to make it more sturdy, less droopy.

My next project was done with dried leaves I've kept in old catalogs for years. I used dark iridescent glass, added the leaves and sprinkled clear powder over the entire glass piece. Removing the leaves was a little easier than the stencil, as long as you kept a stem off the glass so you could lift up. Needless to say, lots of powder was dumped here too, as you can see! Here the powder has been sifted, the leaves removed, and you can see the iridescent glass showing.

The four pieces all got clear glass bottoms, and here they are in the kiln waiting to be fused.

Here they are after cooling overnight ... and looking pretty good!

My first projects were done with a wonderful bamboo stencil. I made two similar plates, so I'll only show you one. I first made masking tape handles for the stencil so it could be easily removed from the glass. I used French vanilla glass and dense white powder for these pieces. In this photo, the stencil sits on the glass piece, ready to receive powder.

I've sifted the powder onto the stencil.

Well, the stencil wasn't that easy to remove, as the powder weighed the stencil down so lots of it fell off and the powder image was not crisp. I dumped several stencils of powder and finally got a fairly good image. Next time I'll try adding BBQ skewers or a cardboard frame around the stencil to make it more sturdy, less droopy.

My next project was done with dried leaves I've kept in old catalogs for years. I used dark iridescent glass, added the leaves and sprinkled clear powder over the entire glass piece. Removing the leaves was a little easier than the stencil, as long as you kept a stem off the glass so you could lift up. Needless to say, lots of powder was dumped here too, as you can see! Here the powder has been sifted, the leaves removed, and you can see the iridescent glass showing.

The four pieces all got clear glass bottoms, and here they are in the kiln waiting to be fused.

Here they are after cooling overnight ... and looking pretty good!

Friday, July 3, 2015

THE FINISHED COBALT PLATE!

I'm so happy with the plate. Got up at 4:00 a.m. to get it out of the cooled kiln. The overglaze really looks good and covered all of the dull areas. Here are a few photos. Oh yes, another thing ... the customer wrote to say she really needed a 12" plate, so ... sorry!

Thursday, July 2, 2015

PROGRESS ON COBALT BROKEN BOTTLE PLATE

Since my last post, I had to add more small glass pieces to an edge that was very fragile, so this piece has already gone through its second firing. Remember the photo with the drawn 12" square and the arranged glass pieces? Well ... you can see by looking at it that there is an inch around the whole piece, so it is not an 11" square. Duh. A senior moment ... it is a 10" square.

Early this morning I sprayed it with a light coating of Clear Coat Overglaze. When you fire a broken bottle, there are spots that look like devitrification and the glaze helps.

Here's the piece with the spray.

The piece will slump today in this beautiful stainless steel mold. I ordered it many years ago and have never used it. It got sprayed with MR-97.

Here's the piece nestled in the mold on the kiln shelf. Keeping my fingers crossed!!

Early this morning I sprayed it with a light coating of Clear Coat Overglaze. When you fire a broken bottle, there are spots that look like devitrification and the glaze helps.

Here's the piece with the spray.

The piece will slump today in this beautiful stainless steel mold. I ordered it many years ago and have never used it. It got sprayed with MR-97.

Here's the piece nestled in the mold on the kiln shelf. Keeping my fingers crossed!!

Tuesday, June 30, 2015

BROKEN COBALT WINE BOTTLE PLATE

I had a request for a broken wine bottle plate measuring 12" square through my Etsy shop. I have had two large cobalt bottles sitting for years waiting for this sale! My daughter gave them to me. So I got out a heavy plastic bag and a hammer and started breaking up the bottle. It didn't take long.

You can see that the pieces are covered with fine glass dust and have to be cleaned. Yes, I did it individually. I suppose I could have put them in a bucket with Dawn, shook them about, rinsed them. But they would still have had to be dried ...

Here are the sparkling clean pieces ready to assemble into a square plate.

I drew a 12 inch square on thin fire shelf paper, and unfortunately the glass from the bottle didn't fill the square. So it will be an 11 inch square plate. You can't add glass from another bottle ... the glass may not be compatible and it might crack next week ... or in a few months. The piece is firing tonight, so I'll keep my fingers crossed that it looks ok in the morning. It will still need a second firing in a mold.

You can see that the pieces are covered with fine glass dust and have to be cleaned. Yes, I did it individually. I suppose I could have put them in a bucket with Dawn, shook them about, rinsed them. But they would still have had to be dried ...

Here are the sparkling clean pieces ready to assemble into a square plate.

I drew a 12 inch square on thin fire shelf paper, and unfortunately the glass from the bottle didn't fill the square. So it will be an 11 inch square plate. You can't add glass from another bottle ... the glass may not be compatible and it might crack next week ... or in a few months. The piece is firing tonight, so I'll keep my fingers crossed that it looks ok in the morning. It will still need a second firing in a mold.

Thursday, June 11, 2015

MORE EXPERIMENTS WITH POWDERS ON FIBER

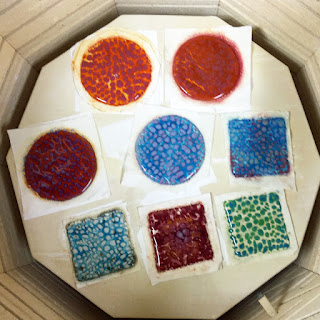

It's been a couple of weeks since I fused glass ... and I'm sure my electric bill this month will reflect that fact! This time I experimented with different powder combinations and made smaller pieces out of my scraps of glass ... four squares and four rounds.

The first step was to layer the powder combinations onto 1mm fiber. This photo shows the pieces after the first firing. The powder has turned into little "puddles".

Kind of interesting ... but not very impressive ... right?

Here are a few close-ups of the pieces at this stage.

I really worried about the piece on the right ...

At this point, I added a contrasting powder to the top of each piece. A long process, as the powder had to be removed from the top of every "puddle"! Crazy. These pieces were then fired a second time and here is the result.

A little more interesting, aren't they? Next, the edges were finished and another piece of glass was added to the bottom of the pieces. All got a piece of black, except for one clear (bottom center). Here they are after the THIRD firing.

A close-up of the round pieces.

And the square ones.

These were great test pieces. Keepers, for sure!

The first step was to layer the powder combinations onto 1mm fiber. This photo shows the pieces after the first firing. The powder has turned into little "puddles".

Kind of interesting ... but not very impressive ... right?

Here are a few close-ups of the pieces at this stage.

I really worried about the piece on the right ...

At this point, I added a contrasting powder to the top of each piece. A long process, as the powder had to be removed from the top of every "puddle"! Crazy. These pieces were then fired a second time and here is the result.

A little more interesting, aren't they? Next, the edges were finished and another piece of glass was added to the bottom of the pieces. All got a piece of black, except for one clear (bottom center). Here they are after the THIRD firing.

A close-up of the round pieces.

And the square ones.

These were great test pieces. Keepers, for sure!

Sunday, May 24, 2015

LATEST POWDER ON FIBER PROJECTS

Life is full of successes and failures. I've had so many successes lately in this new technique of using powder on fiber, that a failure is hard to take. Here is my latest piece, starting from the first firing that developed into "puddles". This was pink powder.

Then for the first time, I added a second color powder, orange, onto the fiber, covering the puddles of pink. Lena's instructions said to spray water over to clean off the fired puddles. I did that on one piece (a real mess), and on this piece decided to use a fan-shaped brush to clean off the orange powder. It worked well, less messy, still took a long time. Here is the piece after the second firing.

It still looks questionable, doesn't it. Well, I forged onward and added a piece of black glass that was cut slightly larger. It is simply beautiful. It is unbelievable. It doesn't look like the same piece. It will be slumped in a 7" square mold.

Now for the failure. I haven't been able to look at this piece for days, as it would have been fantastic. BUT it developed a bubble on the surface. I'll eventually try to grind it, add a layer of clear powder to the top and refire it. I had success with one other piece with a bubble, so maybe it will work. My friend added a decal to cover an imperfection, so that is also a possibility. This piece is about 4" x 12".

Then for the first time, I added a second color powder, orange, onto the fiber, covering the puddles of pink. Lena's instructions said to spray water over to clean off the fired puddles. I did that on one piece (a real mess), and on this piece decided to use a fan-shaped brush to clean off the orange powder. It worked well, less messy, still took a long time. Here is the piece after the second firing.

It still looks questionable, doesn't it. Well, I forged onward and added a piece of black glass that was cut slightly larger. It is simply beautiful. It is unbelievable. It doesn't look like the same piece. It will be slumped in a 7" square mold.

Now for the failure. I haven't been able to look at this piece for days, as it would have been fantastic. BUT it developed a bubble on the surface. I'll eventually try to grind it, add a layer of clear powder to the top and refire it. I had success with one other piece with a bubble, so maybe it will work. My friend added a decal to cover an imperfection, so that is also a possibility. This piece is about 4" x 12".

Subscribe to:

Posts (Atom)